Supply chain tech stack: can CPUs, GPUs, and sails clean up shipping?

|

Getting your Trinity Audio player ready...

|

Cargo ships are giants of the sea and underpin global supply chains. And if stats are your thing, container shipping is a fascinating industry to consider. A very large container ship traveling on a round trip from Europe to Asia and back will consume 7000 tons of fuel oil. Filling up one of those ships takes 10 hours, even using high-speed re-fuelling rigs. And while massive container vessels are the most efficient way of moving goods around the world, burning huge amounts of fuel adds up. In fact, those numbers are so large that operators are considering adding sails to their container ships, and advanced computing is putting wind in this next-gen supply chain tech.

Saving fuel is good for business. But the most urgent need is an environmental one. In 2017, campaigners warned that if the shipping industry for commercial goods was a country, it would be the 6th largest polluter on the planet. Operators such as shipping giant Maersk have reduced the emissions per container moved by 46% from 2008 to 2021, but those savings have been neutralized by the growth in global trade, and CO2 output is still high.

READ NEXT

AI digests supply chain risk

Ultimately, the only solution is to lean on cleaner supply chain tech to bring CO2 emissions down to zero – an ambition that Maersk has committed to achieving for its 700-plus fleet of ships by 2050 at the latest. Maersk’s strategy is to focus on renewable biofuels such as green methanol, and the company plans to introduce several pilot-sized 175m-long ocean-going vessels in 2024 to test the water.

As emissions reporting ramps up, enterprise customers are needing to find cleaner ways of transporting their products to make good on their climate pledges. Electrification is all the rage in the automotive sector, but running ships on battery power alone doesn’t scale as well at sea, compared with electric vehicles (EVs) on the road. EVs can be charged mid-journey if required, but container vessels travel thousands of nautical miles and bulky batteries take up cargo space.

Re-thinking supply chain tech

Autonomous electric ships such as the Yara Birkeland, which went into commercial operation in the Spring of 2022 – transporting fertilizer between Norwegian ports – can save 40,000 truck journeys a year. But there are limitations for operators looking to adopt this technology more widely.

We are proud to say that a number if our @NorthSeaRegion projects are doing amazing things on this front! To name just 2. Our @WindWasp project is using the power of the wind for greener travel. And our #ZEMPorts project is helping to move ships to #hydrogen engines.#interreg https://t.co/oIGgAAXeb1

— North Sea Region (@NorthSeaRegion) September 30, 2022

The Yara Birkeland can travel around 80 nautical miles – orders of magnitude less than diesel-powered ships. And it would take 200 Yara Birkelands to carry all of the goods transported by a large container vessel. But there is supply chain tech capable of going the distance.

In the energy sector, windmills are back in vogue. Some days half of the electricity demand in the UK is met by wind power thanks to large arrays of turbines operating out at sea (the informative National Grid ESO carbon intensity app has up-to-date details). And wind power could make a comeback in shipping too.

Japan’s Shofu Maru was named ‘Ship of the Year’ in 2022. And the reason for winning that accolade was the success of a hard sail wind propulsion system, dubbed Wind Challenger, fitted at the front of the vessel. “The introduction of the Wind Challenger is expected to reduce greenhouse gas (GHG) emissions about 5% on a Japan-Australia voyage and about 8% on a Japan-North America West Coast voyage, compared to a conventional vessel of the same type,” writes the operator Mitsui O.S.K. Lines.

Taking some of the gloss off the achievement is the fact that the Shofu Maru is used to transport coal for consumption by Tohoku Electric Power. But based on the success of the rigid aerodynamic structure – which is telescopic and can be lowered to pass under bridges – Mitsui O.S.K. Lines plans to equip a second bulk carrier with the Wind Challenger system. And this vessel will be used to transport wood pellets supplied by global bioenergy firm Enviva.

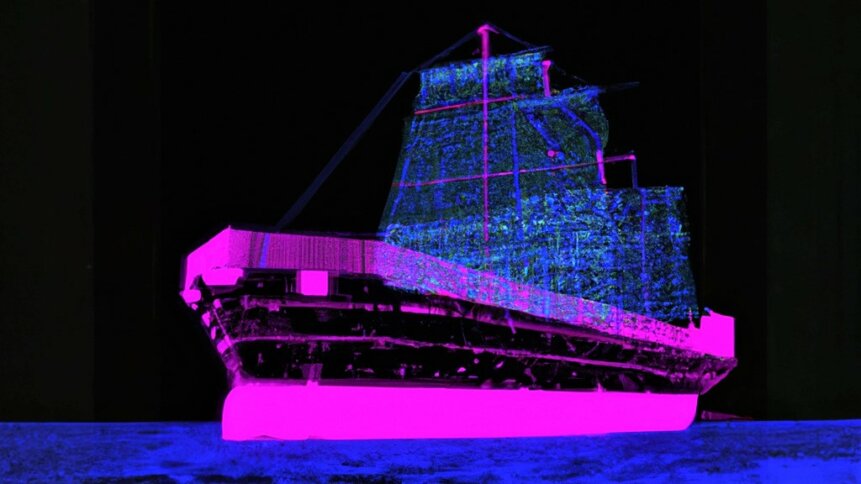

Wind-assisted ship propulsion: Japan’s Shofu Maru, which is fitted with a state-of-the-art rigid sail, won ‘Ship of the Year’ in 2022. Image credit: Mitsui O.S.K. Lines.

One of the concerns for ship owners installing so-called modern sails, such as the Wind Challenger system, is erratic weather. But engineers at the University of Manchester in the UK – publishing their results in the journal Ocean Engineering – have shown how adaptive weather forecasting could reliably amplify carbon savings by maximizing opportunities for wind propulsion.

In their work, the engineers ran computer simulations of 1080 ship voyages traveling eastbound and westbound across the North Sea, South Atlantic Ocean and North Atlantic Ocean. Based on those results, the group believes that wind propulsion along routes informed by adaptive weather forecasting could generate carbon savings of up to 29%.

However, even the most powerful computer models can’t eliminate all uncertainty in weather forecasting, with savings likely to be impacted by 10-20% in practice. However, reducing the emissions of global shipping by 25% by utilizing wind-assisted propulsion would still represent a major step forwards for the sector in meeting its climate goals.

Advanced computing and software tools such as Siemens Digital Industries CFD simulations, which include GPU-enabled acceleration for an extended solver set, can help optimize designs. And shipping tech firms such as Windship are using Formula 1 style wind tunnels to put aerodynamic structures to the test. But making emissions savings is challenging and when you factor in the anticipated growth in world maritime trade, emissions may need to come down by 80% for levels to hit 2050 targets.

However, high-performance computing has a strong track record in solving difficult problems, from beating grandmasters at chess and go, to decoding the human genome. So, there’s no reason to think that banks of CPUs and GPUs won’t be capable of progressing supply chain tech. Certainly, developments in weather forecasting based on ensemble models – where small errors in starting data are propagated to determine the distribution (or ensemble spread) of future weather scenarios – is already helping across multiple industries and driving investments in supercomputing installations and access.

For shipping, moving to the use of cleaner fuels is undoubtedly necessary. But the infrastructure involved in making that transition is considerable and will take time, building on the experience of pilot studies. In Formula 1, progress comes from the additive effect of multiple improvements in car design and operation, and – similarly – maritime transport will benefit too from a combination of technologies.

Computer-designed rigid sails that deliver fuel savings and use wind-assisted propulsion to reduce CO2 emissions are a strong prospect for an industry that has long had to deal with challenging conditions.