Electronics recycling – cheese waste has a taste for gold

|

Getting your Trinity Audio player ready...

|

“E-waste is going to be the richest ore of the future,” proclaims Jason Gaber, owner of Mount Baker Mining and Metals. Gaber has a YouTube channel where he shows viewers how hammer mills and shaker tables can be used to process component-laden circuit boards and separate plastics from a mix of metals, including gold.

The business of extracting gold and other valuable materials from electronic junk is growing and is even becoming a popular side hustle. One tonne of electronic circuit boards can yield in the region of 0.150 kg of gold, and over double that in silver. Plus, there’s likely to be anywhere from 250 – 300 kg of copper up for grabs per tonne of e-waste.

For years, device users have been throwing away – collectively – billions of dollars in precious metals as they dispose of unwanted electronics.

In the beginning, e-waste was sent overseas to become somebody else problem. But processing e-waste has the potential to be many times more lucrative (and much less polluting) than trying to extract gold and other precious metals from ore mined from the ground.

The ability for environmental clean-up operations to turn a profit is seeing a wave of new e-waste recycling solutions enter the market. And for those can run their operations at scale, there’s money to be made in turning e-waste into gold.

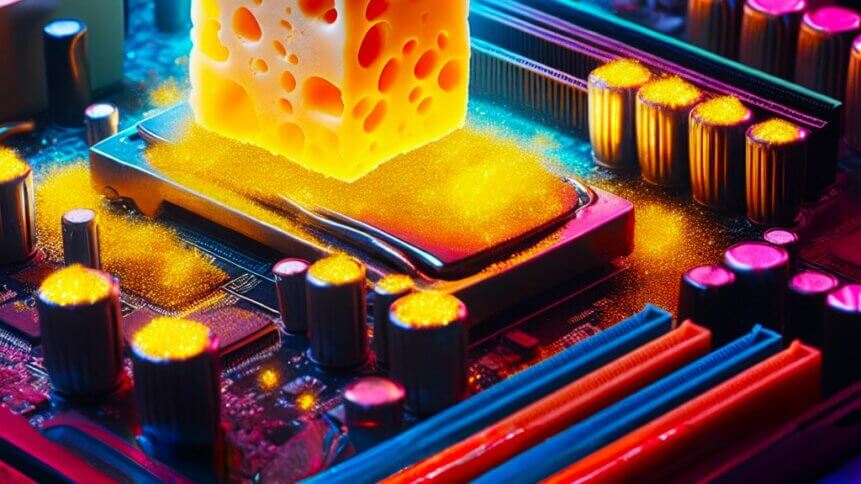

One of the most ingenious approaches – which is still at an early stage, but generating commercially promising results – uses spongey nanofibrils created from a by-product of cheese-making to soak up gold ions in solution and turn them into flakes.

New sustainable method turns waste into gold! ETH Zurich researchers use protein sponge derived from food industry byproduct to recover precious metal from electronic waste. ♻️ https://t.co/LkpuiFUMk1 #ProteinSponge #ElectronicWaste #SustainableGold @MezzengaRaf

— ETH Zurich (@ETH_en) March 1, 2024

Demonstrating the potential of their approach, researchers at ETH Zurich in Switzerland used their cheese waste creation to obtain a 450 mg gold nugget from 20 junk motherboards. According to the team, the material was 90.8 percent pure (21-22 carats), which values the reclaimed gold at around USD 28 – based on today’s scrap gold price.

What’s more, the group claims that the cost of the source materials and energy costs for the process represents just 1/50th of the value of the gold extracted from the e-waste.

Googling ‘how to turn e-waste into gold’ produces plenty of search hits, but many of the recipes feature toxic chemicals. However, by employing a bio-derived ionic sponge, the ETH Zurich researchers believe that they’ve found a gentler path to converting unwanted electronics into valuable materials. And they are not the only ones pursuing more environmentally friendly e-waste processing.

Mint Innovation, whose vision is to become the world’s leading provider of circular green metals, opened a commercial-scale facility in Sydney, Australia, in 2022. According to reports, the operation can salvage USD 85,000 in gold per day from recycled electronics – as well as being able to recover copper and other valuable metals.

Cleverly, Mint’s process –which was developed in New Zealand – makes use of bacteria and fungi that have evolved in regions rich in mine works and abandoned machinery. The organic soup is capable of absorbing metals and Mint exploits those properties to process e-waste in a more environmentally friendly way, compared with conventional methods.

According to Mint, everything leaving its plant is benign, which means that there are no chemical waste streams to be dealt with. And there’s more good news as the process is applicable to other waste stream such as used batteries and catalysts.