Showtime: the art of supply chain gets MOMA nod

|

Getting your Trinity Audio player ready...

|

You might not think to place New York’s Museum of Modern Art (MOMA) at the top of the list if you’re looking to discover more about the supply chains underpinning modern gadgets such as virtual assistants. But if you find yourself at the Midtown Manhattan gallery – which boasts works such as Salvador Dalì’s watch-melting ‘The Persistence of Memory’ and a self-portrait of Frida Kahlo – there’s plenty to learn about the art of supply chain, a blend of natural resources and labor.

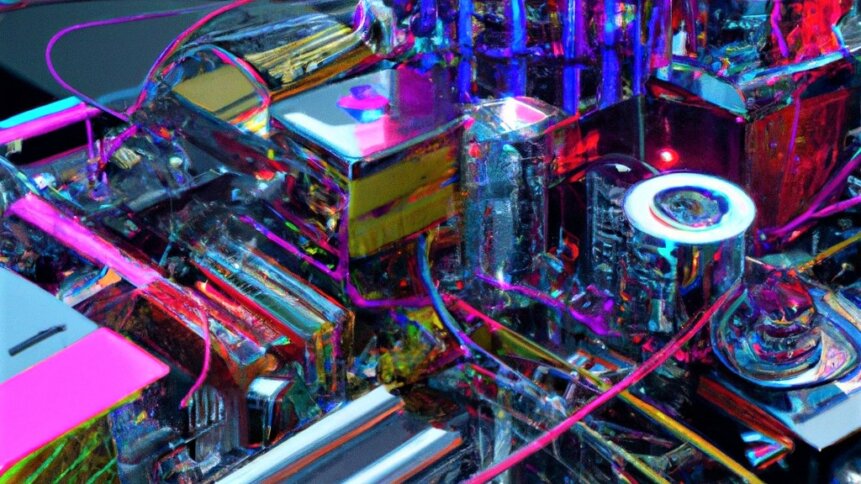

Dubbed simply ‘Systems’ and located on MOMA’s second floor, the art of supply chain themed exhibit features a centerpiece that digs deep into the guts of Amazon Alexa. The show’s star attraction is ‘Anatomy of an AI System’, a data visualization by Kate Crawford and Vladan Joler. And the piece – according to the gallery label – analyzes the vast networks that encompass the “birth, life, and death” of a single Amazon Echo smart speaker.

Art of supply chain

As Crawford and Joler explain, “each small moment of convenience – be it answering a question, turning on a light, or playing a song – requires a vast planetary network, fueled by the extraction of non-renewable materials, labor, and data.” Their study goes into incredible amounts of detail about what it takes to create electronics that many users simply take for granted. For example, the piece highlights the wide range of elements required such as lithium – a prized rechargeable battery material – sourced from southwest Bolivia at an altitude of 3656 m above sea level.

Advances in the art of supply chain management have made the production of electronics – such as the range of Amazon Echo products that shoppers can order online and have delivered to them within hours (depending on where they live) – appear easy. But as The Anatomy of AI makes clear, the complexity behind virtual assistants, smart speakers, and other popular devices is vast and far from straightforward to engineer.

The choice to focus on Amazon’s Echo product is an interesting one as the resources required to engineer smart speakers include the users themselves. “Their voice commands are collected, analyzed and retained for the purposes of building an ever-larger corpus of human voices and instructions,” comment Crawford and Joler in the exhibit notes.

Show me the money

As well as materials, the visualization also includes monthly salary data on the job roles involved in transforming raw materials into smart speakers. At the top of the scale, CEOs are estimated to earn around 16,200 US dollars per month. And, at the bottom, are electronic waste (e-waste) and landfill workers in India and underground miners in Congo, who may take home as little as 100 US dollars per month. Mining and electronics recycling is critical to device production, as no matter how clever the software that goes inside, nothing can be shipped without raw materials.

According to Crawford and Joler’s research, it takes over 110 elements to produce an Amazon Echo device. And, of course, those elements will need to be transformed and combined into components, which then need to be assembled. The diagram points to the scale of the operation and emphasizes the art of supply chain management.

Materials need to be transported from mines to smelters and refiners, and onward to component manufacturers and device assemblers. From there, goods enter distribution chains. But the story doesn’t end when gadgets arrive in customers’ homes. The AI technology enabling voice assistants to respond to smart speaker operators needs creating and maintaining too. And this infrastructure spans from home Wi-Fi routers through internet server provider (ISP) equipment to data centers hosting the speech recognition magic, which puts thousands of GPUs and processors to work answering user questions.

Data center setup and maintenance requires the combined expertise of network engineers, technicians, management, and security teams. Following the threads of Crawford and Joler’s data visualization shows how far the supply chain must extend. And, as visitors to the exhibit (or anyone viewing the Anatomy of an AI System graphic online [PDF]) will already know, there’s more to come. Gadgets break down, fall out of favor, become unsupported, and get replaced with the next shiny thing.

Recycle and reuse

Thinking about end-of-life upfront in the design journey can make a big difference to the environmental impact of electronic devices. And on this front there’s still much for manufacturers to do to lighten the footprint of their products and make electronics much easier to repair and recycle. Shepherding firms toward more environmentally responsible design decisions are campaigns such as repair.eu, which points out that e-waste is the fastest growing waste stream in the world.

E-waste is full of precious metals, which makes it bizarre to learn that 80% of electronics end up in landfill. And this disappointing statistic reveals a key area where the art of supply chain management needs to be improved. Searching on Google Trends for mentions of ‘refurbished’, there’s an uplift in 2020 – no doubt linked to supply chain constraints around the global pandemic. But that trend has tailed off, which is a shame as there are opportunities out there to reduce the burden on the planet caused by our love for electronic gadgets.

However, to avoid ending on a downbeat note, it’s important to highlight pockets of change, such as businesses making devices from upcycled electronic components, which includes guitar amps. And the HP laptop used to type up this article is refurbished. Onwards and upwards.