Eating our way to sustainability – the latest in food technology

• Food technology could tackle our sustainability issues.

• Lab-grown meat and milk could be effectively identical to the animal-based versions.

• Food technology could also help tackle food fraud.

Food technology might not be in the limelight right now, but it could be the answer to the world’s food sustainability problems.

Sustainability is about more than just carbon emissions and electric vehicles. The global food demand is predicted to increase by 70% by 2050 – a demand that couldn’t be met ethically or sustainably with current production methods.

One solution to this is cellular agriculture. “Lab-grown” doesn’t exactly sound appealing, but the method being actively explored today uses cells and innovative biotechnologies to produce accessible, ethical, and sustainable agricultural products.

Cellular agriculture is most commonly used to make animal-derived foods and ingredients, such as meat, seafood, dairy products, fats, egg whites and gelatine.

In some cases, with products like milk, the animal can be removed from the equation by using a microbe like yeast or bacteria. In the example of milk made with yeast, the yeast are altered by inserting into them the gene carrying the blueprints for casein, a milk protein.

Milk is usually made by mother cows kept in a lactating state in an industrial setting. Instead, we can make the exact same milk by brewing it, using a culture that consumes simple sugars to make milk proteins. Source: New Harvest.

Since all cells read the same genetic code, the yeast, now carrying so-called recombinant DNA, makes casein identical to the casein cows make in their milk.

Cell cultivation and fermentation are both well-proven methods from the pharmaceutical and biotechnology sectors and are potential game-changers in food production. Actually, animal insulin could be considered the first cellular agriculture product.

Once it was found to be an effective treatment, insulin was collected from the ground-up pancreases of pigs or cattle. Then, in 1978, Arthur Riggs, Keiichi Itakura, and Herbert Boyer were able to insert the gene carrying the DNA for human insulin into a bacteria, so the bacteria could make insulin identical to the insulin that humans make.

Today, the vast majority of insulin is made by this engineered yeast or bacteria. The resulting safety and consistency of insulin supply could be an indication of the potential impact that similar methods would have on food production.

This innovative approach to the production of animal products – that bypasses traditional farming methods – has the potential to overcome six critical challenges:

- Food insecurity

- Deforestation

- Biodiversity loss

- Climate change

- Public health

- Animal welfare

How far this impact can go will depend on decisions made by biotechnology food companies as they move toward commercial scale.

The processes of cellular cultivation and fermentation require precise control and monitoring in order to produce consistent, high-quality results. A bioreactor requires precise regulation of all important parameters such as nutrient concentration, pH, temperature and oxygen content to optimally support fermentation and provide the greatest possible product yield.

The biochemical process is extremely sensitive to change, and if the process is disrupted, all output is unusable.

For this reason, moving from the lab to mass production can be expensive and complicated. There are often high build costs because of the complexity of the systems required for successful cell cultivation and fermentation.

With this in mind, funding from outside the sector may well be necessary.

Food technology funding at the forefront

Venture capital firm Supply Change Capital has invested $40m in food technology. The firm invests in the future of food, and recently closed its inaugural $40m fund. Supply Change Capital is led by Noramay Cadena and Shayna Harris, two industry veterans who met in business school at MIT Sloan in 2009. The partners have made more than 100 investments to date.

The Latina-led firm has invested more than $13 million across 15 early-stage food and agriculture technology companies since June 2021. Investments include deep tech food, agriculture and ingredient companies, supply chain technology, and enterprise software. Latinx, Black, and/or Female Founder/CEOs comprise 80% of the portfolio.

Noramay Cadena and Shayna Harris lead Supply Chain Capital.

“Supply Change Capital invests in the technologies that underpin a more resilient food system. We invest through the lens of climate and culture, table stakes given the current existential crisis that our planet and society faces,” said Harris.

Also critical to investing in the future of the food supply chain is detecting fraud. Although it’s easy to imagine the potential for food fraud in a future where it’s bioengineered, it’s already a huge threat to consumers.

Technology against food fraud

Food fraud occurs when a food supplier intentionally deceives its customer about the quality and contents of the foods they are purchasing.

So, Northern Ireland firm Bia Analytical Ltd has signed an agreement with trinamiX GmbH to develop new technology to detect food fraud in the agri-food chain.

Detecting food fraud is challenging, and it’s hard for consumers alone to do. Food fraudsters are innovative in the ways they avoid detection.

Due to the high demand for premium quality food and increasingly globalized food supply chains, the risk of food fraud is estimated to be high in the Asia Pacific region. Although food technology might seem riskier fraud-wise, cellular agriculture could alleviate the supply and demand issues that enable the currently existing kinds of food fraud.

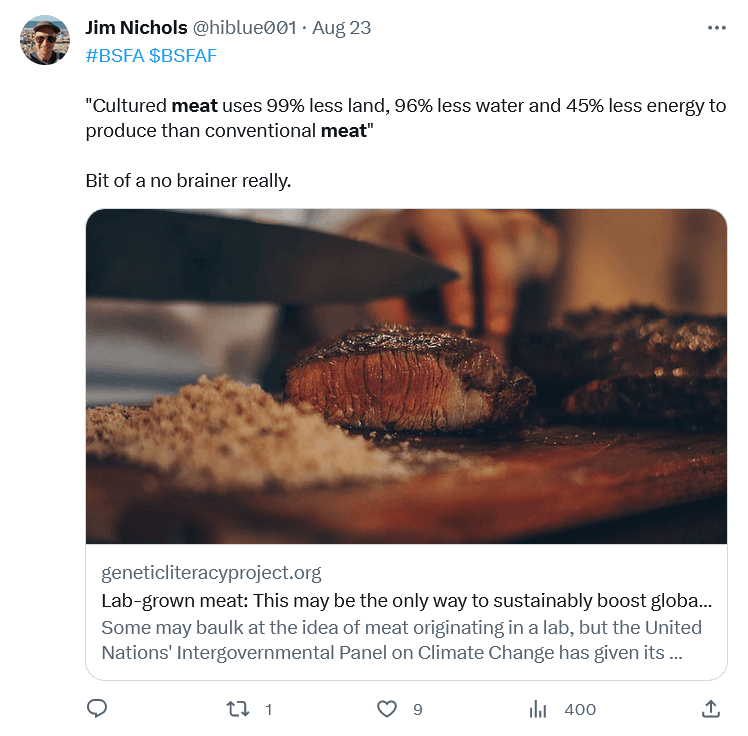

The significant lessening of impact on agricultural land may tip the balance in favor of lab-grown meat.

Already a leading UK food authentication testing lab, Bia Analytical is aiming to take testing out of the lab and provide customers with a rapid, portable authenticity result. The company uses chemometric modelling and artificial intelligence applications to help reduce food businesses’ exposure to food fraud.

German firm trinamiX GmbH, which works closely with partners to introduce immediate material analysis for enhanced decision-making across various industries, has partnered with Bia Analytics to deliver a solution.

Dr Terry McGrath, chief technical officer, added: “I am very excited about this partnership, I have worked in the area of food authenticity for many years and see this as a huge step forward in our ongoing fight against food fraud.”

A way to check the legitimacy of your food will certainly become more and more useful in the face of cellular agriculture. Would you prefer lab-grown or crickets for your buger?