Reducing data center energy and emissions costs – a case study

|

Getting your Trinity Audio player ready...

|

• Emissions break down into three scopes.

• Data center energy demands depend on storage sustainability.

• New technological processes can minimize data center energy demand.

Data center energy and resource consumption is increasingly a major issue in the tech world. The combination of a need for more data centers to power technologies like generative AI, and before long, quantum computing, and the need to decarbonize our impact on the planet before we make largely uninhabitable to ourselves, is a double bind, into which reducing data the impact of center energy slots neatly as a potential solution.

We sat down with Gary Lyng and Ian Clatworthy, VP Product Solutions Marketing and Director of Data Platform Product Marketing respectively at Hitachi Vantara, a Hitachi subsidiary specializing in data storage and analytics, to find out what can be done about the tremendous thirst and emission profile of data centers.

THQ:

Let’s put data center energy into some context if we can.

GL:

OK. Uploading a six-second Instagram video is the equivalent of boiling 22 gallons of water, in terms of the amount of energy it uses.

THQ:

Wha-huh? That sounds insane.

It’s also pretty sobering.

GL:

Now start thinking of petabytes of data.

THQ:

Our brain just started crying and singing Earth Song.

GL:

And people go “Oh, move it into the cloud, oh no, wait, move it back.” Because it feels instantaneous and invisible, right? It doesn’t have that inherent sense of consequence to it, and it’s not their particular problem. But think of the consumer price. That data is being moved around, constantly replicated, fragmented.

And it’s not a matter of controlling it and putting it in one location, so you never need to move it around. To do that, you need to harness it. And you need to have data observability, so you can actually manage the state of the data. Is it operational or transactional? Is it active or active archive? Where should it be? And how many copies are there?

There’s so much over-redundancy.

Everybody wants the cool toys. Nobody ever thinks of the energy costs of running the Matrix.

THQ:

We’re still back at six seconds of Instagram, 22 gallons of water, and petabytes of data. In fact, we’re still back at “Wha-huh?”

IC:

Absolutely. So the first thing to understand when we’re looking at data center energy is really the scope of emissions value chains. This is separate to storage efficiency and what we’re doing with an actual product itself.

There are three levels to this.

The scope of the issue.

THQ:

Scopes 1, 2, and 3?

IC:

Right. Scope 1 is direct emissions. This is everything from power that’s produced onsite and boilers to salespeople’s cars. It covers everything that a company has control over.

Scope 2 is your indirect emissions. So this is electricity you’re purchasing from the grid and used by an organization. And then you also have other indirect emissions.

And this is the hard one. Scope 3 is the emissions that you have no control over whatsoever. So that’s your emissions that are coming from the company you’ve bought things from – including your electricity.

Emission scopes – got to track them all.

YOU MIGHT LIKE

The challenges of Scope 3 data collection

This is now a megatrend for us. And we’ve been surprised by how fast the adoption has come in. But what we’re seeing now is this huge uptake. If I’d talked about Scope 3 in January in the States it would have been merely “interesting.” Now it’s a must-have.

I was just in a major meeting, and the potential client said “There are two things that interests me. One is sustainability. And the other is how you’re going to understand my data.” The rise and rise of understanding and enthusiasm for sustainability has been astonishing.

We take all this very seriously – we’re the first Japanese company to be a COP26 member. And while we think we’re good on emissions, this is not a world in which you can write a report and go “Hey, look, we’ve measured ourselves against ourselves, and we think we’re really good on emissions,” so we’re actually being externally ratified, which is the most important thing.

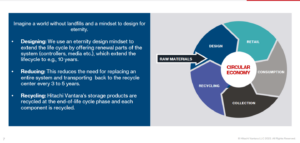

Circular economics.

Circular economics is vital to understanding the CO2 footprint of a solution. This is not down to efficiency once you’ve bought it, this is prior to that, it’s what’s locked into that product before it’s even installed in your data center. So how we purchase raw materials, where our silicone is manufactured, where our metals are produced, how it’s then shipped to our manufacturing facility in Japan, how we press that material, design it, ship it, and we’ve even been looking at the CO2 impact of designing the software even, and adding that into the lifecycle of the product as well.

But equally we’ve been looking at delivery, and we’ve stopped using cardboard in favor of a fully reusable solution, and added a full recycling stage into our inventory as well.

Circular economics is crucial to sustainability.

THQ:

So much for the incidentals that feed into data center energy and emissions. Let’s talk big.

Reducing your carbon footprint.

IC:

Absolutely. Our distribution center in Europe is in South Baumel in the Netherlands. And this is entirely energy neutral. It’s the largest unsubsidized solar project in a single building in Europe, so it represents no energy consumption at all.

That building is not only self-supporting, we actually sell surplus geothermal energy to the building next door. Naturally, the building uses rainwater to flush toilets, and so on.

The self-sustaining data center – the way of the future?

READ NEXT

Smarter procurement and Scope 3 data

All of which is great, but the only thing that we keep coming back to is that the product that’s installed in your rack, the thing you’re actually going to utilize in your company, has a CO2 footprint, regardless of where it’s come from, because of that circular economics.

So if I take a solution that’s been manufactured in China, for example, versus one that’s been manufactured in Japan, the difference is 38% less CO2 in the Japanese box.

And that’s purely because from manufacturing. This is well-publicized globally, that in Japan, users consume less CO2 in manufacturing than Chinese consumers do, because the majority of power plants in China are still coal-fired.

The challenges of sustainability.

So, regardless of how energy efficient your data center supply chain is, you have to bring in storage sustainability. And that means you need to understand what the CO2 footprint of your data storage is.

Real cost savings.

We have the Energy Star certification, which proves we really measure all our sustainability from circular economics. But we also have really power efficient products too, which helps deliver data center energy efficiency day to day.

So what does that mean, when you put everything together? It shows that our CO2 emissions over our product lifecycle have reduced between 30 and 60%, compared to previous years. And these numbers are not coming us, they’re coming from external ratification.

So how do we do that? Well, we have data compression, that’s not new, but it’s actually all about visualizing what that means. It means we’ve improved by around 100 tonnes of CO2 – mostly because we’re compressing the data in an efficient way, with unique hardware and our own algorithms that are Hitachi IP.

There’s also the addition of automated compression switching, where we’re actually using technology itself to lower the power consumption of the box when it’s not in high demand. We switch from inline to high performance inline compression to post-process compression to utilize less CO2.

And we’re going to see this again, as we move to our next generation data centers. We’ll be able to underclock the CPUs on the fly, and actually utilize less power in the data center. So again, AI engineers are really pushing hard to bring that technology into the data center.

THQ:

Yes – underclocking and switching seem to be the favorite technological enhancements mentioned when we talk to people about “greening” their data center energy requirements.

A fuller picture of sustainability.

IC:

Yeah. For us, that’s something that came in with our E-Series products as well. It’s about two years old. And again, all of that’s helping towards changing the customer conversation. Now, everybody’s interested in storage efficiency. But that’s table stakes, right? I expect all my vendors to say that.

What I want to be able to do is – without greenwashing – to be able to go to the board and say “Look, here’s the end-to-end lifecycle of a vendor we’re working with, where they bought their materials from, how they’re manufacturing and how they’re shipping?”

And that’s really where we’re seeing at the moment. Big customers coming to us and saying “We need to be competitively sustainable. And if we’re not, we’re gonna lose. We’re just we’re not going to be around.”

In Part 2 of this article, we’ll dive into understanding the data, and how that plays into data center energy costs – both economic and planetary.