Robotics in warehousing – where your technology strategy should start

Any modern warehouse technology strategy will have robotics at its heart. That’s simply a factor of how many roles modern robotics can fill within warehousing – from pickers to fillers to stackers to packers. Robotics in warehousing are as fundamental, assuming you want to go about things in a 21st century way – as shelves and products, and arguably more fundamental to the whole process than human beings.

What’s more, the more development (and, necessarily, the more development finance) that goes into robotics in warehousing as time goes on, the more variety there will be, the more specialization (and perversely, also the more multitasking), and the greater flexibility in terms of deployment, financing, and upgrades.

If you don’t want to get caught in the 20th century, robotics in warehousing is where your technology strategy should start.

Science fiction is now commonplace.

Robotics in warehousing can be divided into hardware and software – the actual mechanical body with its range of potential functions and capabilities, and the software that turns it into something more than a coffee table, and makes it your warehouse’s best friend.

Ten or twenty years ago, it would have been science fiction to say that both these things were within the budget of many businesses, even down to smaller operations.

These days though, you can often buy – or rent, as part of a robotics-as-a-service model – the robots, the warehouse management system, the software, and the expertise to make Robot A do the things you need Robot A to do, and Robot B, likewise.

And robotics in warehousing have been almost instantly transformative in terms of technology strategy. Many smaller businesses – and indeed, many larger businesses, too – have always needed warehousing space to hold products until they’re sold. But until the age of robotics, that has always come with either additional staff costs, or additional personal hassle when it came to the points of loading and fulfilment.

Staff – or business owners – would always have to be there to unload products from trucks, drag them to their correct location, and use whatever technology they could (and that they were licensed to use, in the case of machines like forklifts) onto the right shelves or pallets.

Then at fulfilment time, the whole process would have to be gone through again, while also managing the manual restocking process.

This would either be costly, or it would significantly eat into the business owner’s time, life, and physical strength. It was clunky, disconnected, and prone, as ever, to human error.

The dawn of robotics in warehousing.

The dawn of the age of affordable robotics in warehousing has gradually put an end to that situation, and with the right robotics, warehousing businesses can almost run themselves – certainly they can reduce the business owner’s involvement in the process to something altogether more office-based and executive.

Why are robotics so fundamental to modern warehouse technology strategies? Largely because of the relatively recent proliferation of robots, their various types and functions. That has meant that there are very few on-the-ground roles within a warehouse that really, truly need a human to perform them.

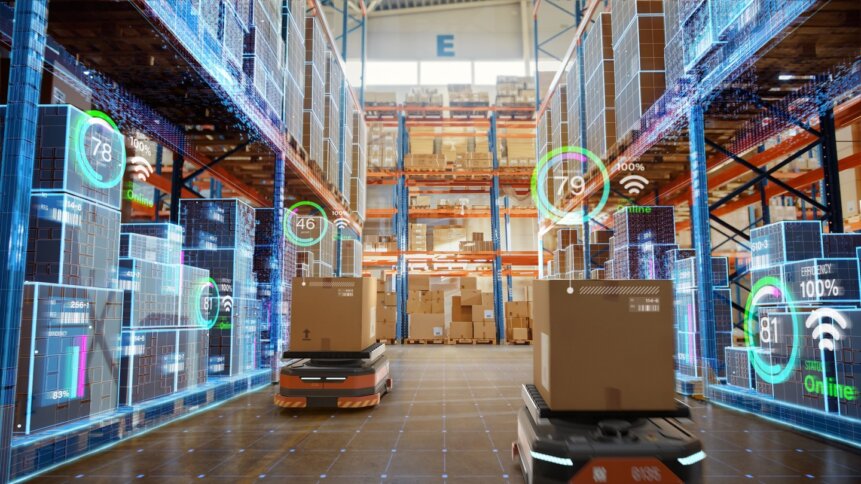

That diversity of robotic roles can mean you have AGVs (Automated Guided Vehicles), or these days, more likely AMRs (Autonomous Mobile Robots) to take things from A-B – in the latter case, guided by program and sensors, without real-time human intervention.

Similarly, you can have UAVs (unmanned aerial vehicles), guided by humans, or aerial drones (unmanned, human-free) that can scan difficult-to-reach areas and auto-update your inventory records, or even record evidence of necessary maintenance you can’t see with the naked human eye.

Robot arms can be pickers, packers, checkers, or assemblers (remember what we said about multifunctionality?) depending on your needs. They’re relentless, they’re fast, and they mostly don’t require human intervention – meaning that neither you, nor anyone you’re paying, have to stand there and watch them work.

Automated storage and retrieval systems (AS/RS) are all about the movement of stock – which can involve either lifting ridiculous amounts of product, far more than a human could at any one time, or using automated crane arms to pick specific products off shelves.

Show me the money!

This is what we mean by the diversity of robots radically reducing the need for human involvement in the day-to-day warehousing task.

But just because you can use them to do all this, doesn’t necessarily mean that you should, right? What’s the actual business case for adopting robotics in warehousing?

First and foremost, it means you can cut the number of humans doing the jobs. That means each robot only has to cost you less per year than an equivalent human’s salary to be an above-the-line saving.

Bu there’s more to it than that. Secondly, there’s a significant reduction in human error, meaning a slicker, faster, more perfect operation with less wastage.

Predictable breakdowns.

On top of that, warehousing is a potentially dangerous, and often strenuous job for human beings – the stretching, the bending, and the ever-present risk of injury up ladders, or from falling stock. With robots, not only are they less prone to injury, if something falls on them, you’re not dealing with healthcare insurance, Workers’ Comp, or industrial tribunals. You simply change them out, put in a replacement robot, and go about your day.

And while robots absolutely do have maintenance costs attached to them, that maintenance, and therefore those costs are predictable, meaning you can plan for them ahead of time, both in terms of outage, replacement, and cost – for instance, doing refits and refurbishments in quiet months, rather than in the run-up to Christmas.

There’s also precious little lag time in terms of orientation when it comes to adding new robots to your warehouse in those times of higher need. Apply the software, and boom – new robots, dealing with increased demand, certainly within the week and often within a day or two.

So, robotics deserve the central place in your warehouse technology strategy, because:

- Their diversity means you can essentially “hire” exactly the right workers for the job.

- They can do things that it’s dangerous for humans to do.

- They can automatically update warehouse management systems with fresh data.

- They’re an economical choice, with little of the uncertainty that comes with human workers.

- With some new funding models, you can easily add in extra robots to deal with peak demand, without being forced to use them all year round.

Robotics in warehousing are a technology that’s been waiting for its time to come, and evolving all the while it’s been waiting. With leading players like Amazon having shown the variety of ways in which they can improve not only the speed of delivery, but also the safety of operations and the bottom line of the company, they’re a technology whose time is now.