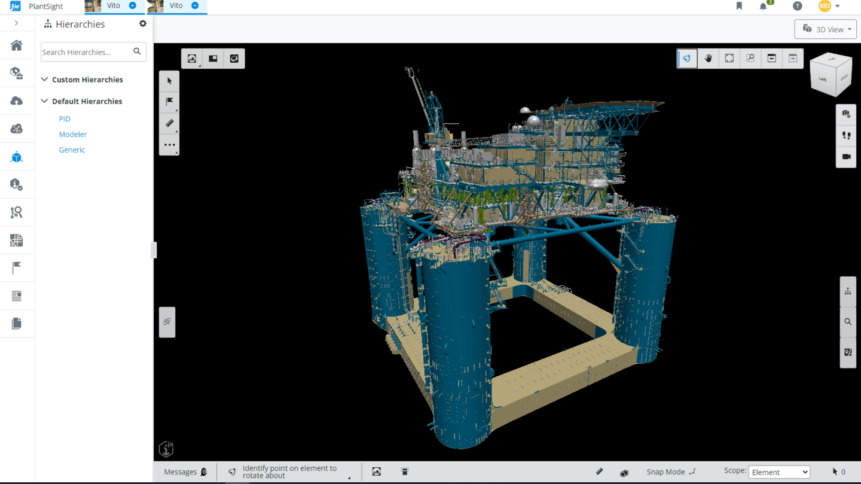

Data democratization and digital twins in power generation

|

Getting your Trinity Audio player ready...

|

At the Bentley Systems Year In Innovation event in London in November, 2022, we sat down with Allistair Stubbs, Vice President, Asset Operations for Bentley, and Richard Irwin, Senior Solutions Marketer, to find out more about the company’s ongoing work in the field of power generation. Using digital twins and data democratization, designers and developers are delivering new power stations – and reimagining old ones – to essentially keep the lights on across the world.

READ NEXT

Digital twins in power generation

In Part 1 of this article, we discovered some of the leading challenges in the world of power generation – uneven distribution of power, a growing need for a multi-modal power model, and in some cases, the loss of essential knowledge in the industry. We then turned the talk to the power of data democratization.

Power through democratization.

THQ:

There’s a lot of talk about data democratization across the board at the YII event, and the idea that it offers huge benefits wherever it appears, even though we don’t know what some of them are until we unlock them. Does that apply to power generation too?

AS:

Oh, definitely. There have been some interesting challenges with our users who have brought data together in the GIS (Geographic Information System) space. For instance, power generation and power transmission are different disciplines. In the past, they’ve used different coordinate reference systems and different Mercator-like projections onto the globe. That doesn’t matter if you’re just looking at modeling a building, because it’s nothing far enough apart to especially register. But when you start modeling larger areas, like a distribution network, these people are discovering that that their information doesn’t even line up. And it never matters until you try and line it up.

It’s one of those things where nobody realized that this department was using this reference system, and this one over here was using a different one. It never mattered when they were just working in their own areas. Bring it together and all the data is wrong. That’s what happens with data democratization – you start knowing how other teams are doing things, and recognizing the changes that need to be made to achieve a joined-up system.

THQ:

That’s something we’ve heard from electrical grid people too – having access to more data, or more precise data, exposes the fact that a team may well have had a way of doing things, but it’s been isolated and doing it that way historically “because that’s the way we do things,” and when the data is democratized, it opens up not only potentially better ways of doing things now, but also makes them question quite why they’ve done things that way for all that time.

RI:

It’s finding insights, certainly. There may have been good questions to ask, but within a data silo, they’re unlikely ever to be asked. And you’re never going to know the answer to the question you never asked.

AS:

That’s an interesting way of phrasing that question, because what we’re seeing as well is where people have been doing something for a while, and you’ve had a few people changes over maybe 10 years, one key piece of knowledge the department or the organization has lost is why they did it. And rediscovering the why is a fundamental piece of engineering knowledge that has in many ways been dissipated over time. And so the “why” is “because the process says,” rather than “why the process was put in in the first place.”

Better maintenance through visibility.

Digital twins are enabling better visibility of maintenance information, you know? Different techniques for monitoring substations, transformers, oil monitoring, or temperature monitoring. Whatever techniques there are, making that visible more widely is an enormous benefit. Maybe two different substations are encountering the same problems. Nobody knew before because they’re two different units, and they had no reason to ask or talk to each other about it.

THQ:

So that’s one of the big benefits of data democratization in the power industry? Showing teams and organizations potentially common issues that they never knew existed.

Again, talking to people in the electricity grid and power supply industry, they’ve said that digital twins and asset management allows you to do preventive maintenance on things to make sure that downtime is either minimal or sometimes even non-existent. In the power generation sector, you assume and hope that that has always been the way, but from the evidence of what happens with data democratization, we’re guessing it actually hasn’t?

AS:

No, and the thing in the power generation sector is that there’s generically a surplus of power. If one part of the grid suffers a failure, it can be supplemented by another point. Because for instance, where you have a national grid, as in the UK, you can move power around very easily. So a failure in one place, or the inability of a power station to start, is just made up by power from somewhere else.

Avoiding outages through advance data.

But it looks like that UK grid will have challenges coming this winter, where we’re at the high 90% capacity level, then a failure might result in temporary power failures. So it will become increasingly important to be able to deliver reliability. What we’ve been doing in our partnership with Siemens is deliver tools that form a reliability package that helps power station owners to look at their assets, identify the criticality of them, and then build a “maintenance twin.”

So we’ll have an understanding of the criticality of any given equipment in the system. Once you have that, you’re making a documented story about it, and so you can show the owner how to regulate it. So instead of just going and maintaining a change in the oil in the transformer, dismantling and rebuilding a pump with power, or whatever, you can remotely detect that there’s a problem. And more importantly, you can detect it in sufficient time to do something about it. That means you don’t get the downside of outages.

RI:

That seems to be one big benefit of digital twins in the power area. There are generational distributions of it, so that it can hand things off. And it can do it safely without having to go to everything. It can all be checked from the center.

New global opportunities.

AS:

Yes, it’s enabling new opportunities as well. How do you go and inspect all of those cables? All the insulators? Now you can do it with drones, which is a lot safer than having humans climb all over the system to check for maintenance criticality.

And you can involve other people much more easily, of course. If you find a crack, the next question is “Well, is that crack important?” You can talk to your insulator specialist, who could be on the other side of the country, or the other side of the world. That’s a double win for digital twins and data democratization – you can get things checked easily and quickly without sending in teams to either a) find cracks in the first place, or b) investigate whether they require action. It helps not only deliver better power generation services, but also to improve the sustainability of a plant.

THQ:

So in a sense, it’s sustainability in two directions at once. Both in terms of reducing downtime and potential outages, and in saving enough money through data modeling to keep the operation running.

RI:

Exactly.

AS:

A lot of what we’re doing relies on openness to deliver sustainability. A lot of the infrastructure projects we’re involved with are going to be running for 30, 40, 50, even 60 years. So for an owner-operator, it’s critical that they’ve got access to that data, not just now in today’s system, but in five years, and ten years, and so on.

Being open is important for the supply chains too, whether it’s for the engineering, for the plant, for the transmission system, you know, those supply chains are changing as well and they’re getting more complex. They’re going to China, and they’re using multiple different software systems for design as well.

With an open system, with data democratization, you can manage the data that you have right now, and then curate it or sustain it into the future. That’s critical for the future power generation industry, I believe.