Infrastructure digital twin projects lauded at Going Digital awards

In Part 1 of this article, we took a whirlwind tour through the first five infrastructure projects that earned their teams a Going Digital award at this year’s Bentley Systems’ Year In Infrastructure conference in London, UK.

There we saw innovative projects in the fields of: bridges and tunnels; construction; enterprise engineering; faculties, campuses and cities; and geoprofessional. But as a showcase of the almost infinite variety of use-cases of the new digital infrastructure tools, up to and including digital twins, there are seven whole other categories of project that earned their teams Going Digital awards this year in London. Between them, they paint a picture of the ways in which the technology is changing the world right now – and to some extent, how it will continue to shape a safer, more easily maintained, and relatively stress-free built environment in the future. Let’s take a look at the rest of the Going Digital award-winners this year.

More of the best digital twin use cases

Grid

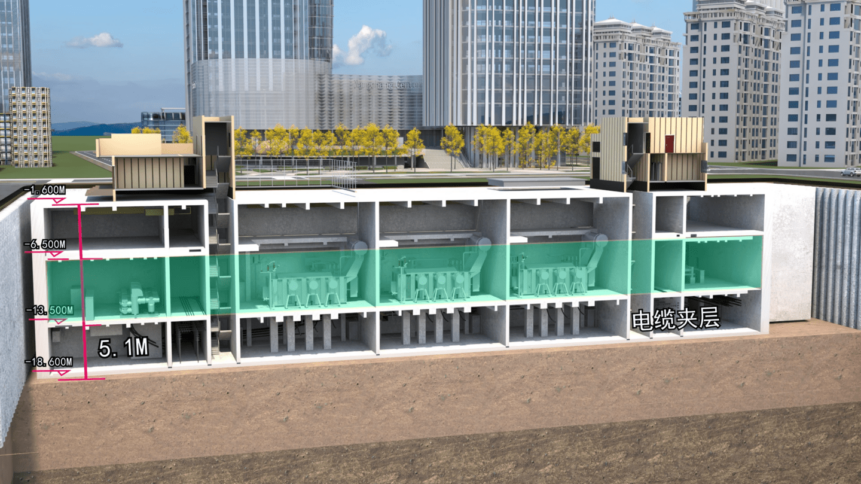

PowerChina Hubei, for its full life cycle digital application at the Wuhan Xudong 220kV substation project.

Wuhan Xudong is central China’s first fully underground 220-kilovolt substation and is a pilot demonstration project for Wuhan to build a first-class power grid, providing electricity for 200,000 residents in northern Wuchang.

Located underground near the Yangtze River in a densely populated area, the project required a lot of coordination and a short construction period. The project team wanted to implement life cycle 3D digital workflows and planned the substation layout, reducing total land area by 52.42%, avoiding more than 50 reworks, and saving CNY 3 million in project changes.

Process and power generation

OQ Upstream, for its work on asset reliability digitalization.

OQ is an integrated energy company, which operates and manages dozens of plants, thousands of assets, and over 4,500 kilometers of pipeline across Oman.

It had a need to improve its asset performance and reliability, while ensuring that plant operations remined safe and reliable. OQ chose to digitalize its asset management processes, to retire a scattered and widespread set of paper assets and improve its asset maintenance methods.

It established a centralized digital asset performance management (APM) system, incorporating failure reporting and analysis, asset health indicators, and digital inspection strategies into the system, so it could perform corrective maintenance management. The digital solution saved 14.8% in total maintenance costs and reduced functional failures by 50% to achieve an annual operational reliability growth of 4.3%.

Rail and transit

PT Wijaya Karya (Persero) TBK, for its work on the integrated high speed rail and station at Jakarta–Bandung.

The integrated high-speed rail project between Jakarta and Bandung is intended to reduce congestion between the two cities and foster a culture of public transportation in Indonesia.

It’s 143 kilometers in length and has many complex structures along its length, providing a significant design challenge. The project also had to be completed during the Covid-19 pandemic.

featuring various structures, the project presented geological and coordination challenges, compounded by an accelerated project schedule amid a global pandemic. Having used 2D design and conventional survey methods on past projects, resulting in delays, additional cost, PT Wijaya Karya (WIKA) deployed an integrated BIM and digital twin solution, developing a connected digital ecosystem and a single source of truth. That allowed it to deliver dynamic modelling and an intelligent digital twin. The integrated solution streamlined workflows, improved efficiency, design quality and calculation, and saved USD 185 million in construction costs, cutting six months off the construction schedule in the process.

Roads and highways

Waka Kotahi and FH/HEB JV, Beca Ltd, for its work on the Takitimu North Link in Tauranga, New Zealand.

The Takitimu North Link project is being constructed in two stages by Waka Kotahi (New Zealand Transport Agency). When it’s finished, it will deliver a greater variety of public transport – and better safety – to the Western Bay of Plenty in Tauranga. Better public transport means more economic opportunities and faster population growth. But it’s by no means an easy ride to deliver. Stage 1 is a 6.8-kilometer expressway, including 10 bridges and a separated pedestrian path, through a challenging natural environment, that needs to be constructed with consideration for local residents.

Beca implemented an integrated, model-based digital approach to address the site complexities and coordinate the large, multidiscipline project team.

Beca then established a connected data environment and digital twin that will simplify construction in the difficult location. Collaborative digital modelling and 3D visualization reduced modelling time by 15% and improved design efficiencies by 20%, while achieving higher-quality deliverables compared to previous design methods.

Structural engineering

WSP, for its work on the optimized design of Unity Place in Milton Keynes, UK.

Unity Place will be the new headquarters for Santander Bank, consolidating four existing office buildings into a single state-of-the-art building.

It will be designed from the ground up with green credentials, and efficient working among its highest priorities, while covering some 84,000 square meters.

WSP needed integrated structural and geotechnical modelling and analysis applications to determine sustainable building solutions. Using Plaxis and Ram, it was able to simplify both its design and its workflows to meet the construction budget and timeline while achieving sustainability goals. In fact, by using the modelling and analysis tools, it saved 16,000 tons of unnecessary concrete and £1.206 million in material costs.

Surveying and monitoring

Singapore Land Authority, for its work creating an SG digital twin using mobile mapping.

The Singapore Land Authority thought big in its scale – it initiated a national 3D mapping of the whole of Singapore, using aerial and street mobile mapping. Using the ‘capture once, use by many’ approach, it built a digital twin from over 600 billion point clouds, amounting to 25 terabytes of mobile mapping data, which it then shared with a variety of government agencies and stakeholders.

Using an advanced web-based application, the SLA managed and integrate that colossal volume of point clouds and images, and generated a digital twin from it, bridging data sharing with multiple users via cloud-based resources. When compared with the cost of doing the same job with traditional mapping methods, the SLA saved SGD 26 million, and one whole year of capture and processing time.

And finally…

Water and wastewater

Jacobs and PUB (Singapore’s national water agency) for its work at the Tuas water reclamation plant.

PUB is building the state-of-the-art Tuas Water Reclamation Plant (TWRP), providing a treatment facility for industrial and household wastewater designed to maximize water recovery and reduce energy consumption.

Jacobs is responsible for design and construction management, including managing and integrating digital information across 17 contract packages. Aiming for world-class digital delivery, but faced with challenges coordinating and managing huge amounts data and multiple disciplines, it found its previous software approaches could not handle the workload, so instead it went for a cloud-based digital platform that could deliver collaborative, federated modelling.

Using iTwin, Jacobs established a web-based digital environment and single source of truth, enabling real-time access to a digital twin and democratizing BIM and digital transformation across multiple stakeholders.

The solution automated information extraction, improving engineering quality, efficiency, and collaboration. Establishing a connected digital platform enhanced construction and project delivery and optimized the digital capabilities of the project.

While it’s worth celebrating all these winners, they’re just some of the most eye-catching and clever uses of a technology which is, if not perhaps as fully mature as some, clearly the technology by which the world we know and understand will be defined tomorrow. For every winner here, there are two worthy finalists. For all the finalists, there are almost a hundred projects that were considered for one of this year’s Going Digital awards. And beyond that, there’s an enormous quiet infrastructure ecosystem of projects all changing the world in important ways, and all powered by technology that’s geared specifically to make changing the world and the way it works a more cost effective, more efficient, more elegant, and more achievable thing to do.

The world of the digital twin is here right now. Whether you’re in the infrastructure business, or you need someone who is, make sure you’re on top of the latest tools and techniques in design and development – the chances are high that it will get you better results, lower costs, and a robust, sustainable return on your investment over time.