Learning by example: digital twins show and tell

Digital twins are unlocking a wealth of insights for industrial users thanks to their predictive powers and ability to road-test solutions in the digital realm. More than just standalone simulations, digital twins are computational representations of real-world systems fed with live sensor data, which can operate bi-directionally – monitoring operations as well as providing feedback for decision-makers.

One of the best ways of getting to grips with the technology is to look at the applications landscape and examine how leading firms are integrating digital twins into their activities – delivering benefits for their businesses and driving company growth. And the numbers soon add up. Industry veteran GE reckons that its suite of managed services powered by digital twins has delivered an estimated $1.5 billion in savings to its customers.

Model checking pays back

Managing large infrastructure is a complex business, which has given rise to digital solutions such as building information modeling (BIM). These tools bring together design, construction, and operations data so that all stakeholders – from the architects putting the initial ideas on paper to the management teams responsible for running the finished facility day-to-day – are on the same page. What’s more, with all of the information loaded into a digital platform, operators can run model checkers (programmed with rulesets to cover distances between components, door clearances, and a host of other requirements) to identify any problems in the virtual realm, before they become baked into the real-world.

In a recent case study, Copenhagen Airport’s technical team – who worked with Finnish BIM quality assurance software developer Solibri – explained that model checkers can deliver big savings worth hundreds of thousands of Euros by flagging construction and engineering issues at an early stage in new infrastructure projects. Examples identified include problems relating to the installation of large baggage handling equipment, which if left undetected would have cost the airport a lot of money to remedy.

Getting airport operations to run smoothly relies on the efficient exchange of data, not just internally, but externally too – through projects such as Airport Collaborative Decision Making (A-CDM). Information-rich scenarios represent strong candidates for the deployment of digital twins. And other examples in aviation include sub-systems such as jet engines, where digital replicas can inform performance gains and feed into predictive maintenance.

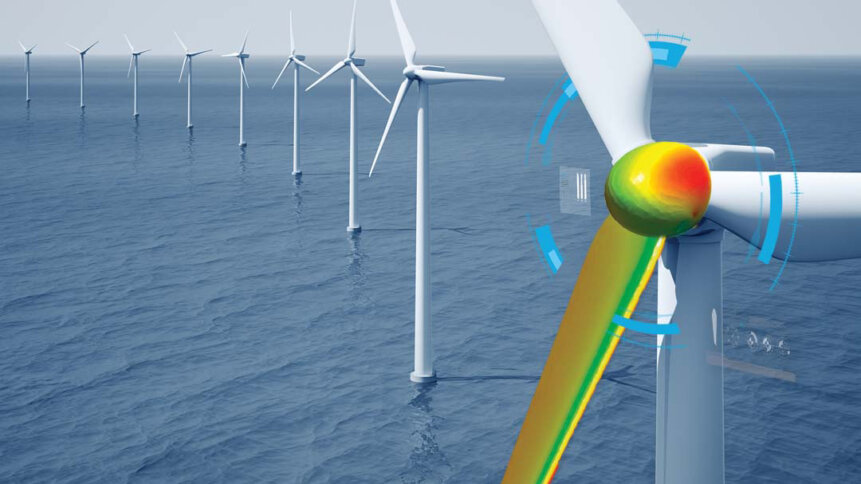

Turning wind into electricity

Renewables firms such as Iberdrola of Spain and Denmark’s Ørsted, which operate wind farms across Europe and beyond, are big believers in the power of digital twins to optimize the energy generating capacity of their turbines. And this appetite for simulation is inspiring processing improvements too. Working with Nordic cloud computing consultants EDRMedeso, Ørsted was able to accelerate its modeling capability so that run time dropped from 30 hours to just 30 minutes. The solution, in this case, was to harness scalable computing resources through Rescale and run Ansys engineering applications in the cloud.

Pay-as-you-go computing plans reduce the infrastructure burden for firms who want to scale up their digital twin activity, motivated by the gains that being able to run more complex digital replicas of real-world systems brings. And providers note this too. In February this year, Ansys announced a strategic collaboration with AWS to transform cloud-based engineering simulations. This builds on its partnership with the web services giant, which has seen developments such as the provision of apps optimized for AWS Graviton2-based instances that feature Arm processors and deliver cost savings to users by running simulations more efficiently.

Evergreen strategy

True-to-life digital twins are helping water companies to optimize their operations, a task that is becoming more important than ever as global warming turns up the heat. This month, US firm Bentley Systems – which offers a platform for building digital twins dubbed iTwin – announced that it had acquired Eagle.io, a provider of cloud-based software for remotely monitoring environmental sensors. The tool provides a valuable dashboard for water treatment plant operators, port authorities, and a host of clients that rely on the publishing of live data logging streams.

The acquisition points to how infrastructure engineering companies, such as Bentley Systems, are bringing IoT platforms into the fold as a way of building evergreen digital twins. Thanks to the integration of continuous monitoring, models are always up to date – adding to their appeal. And it can’t be overstated how important data is in underpinning the relevancy of digital twins.

Industry giant Siemens – who teamed up with Bentley Systems to develop PlantSight, a digital twin for the process industry – advises users to build solutions on a stable data platform to provide the best foundation for gathering insights. Incorporating contextualization and validation steps into the information processing also builds confidence when it comes to interpreting the output from living digital twins and the decision making steps that follow.

These are just a few of the application examples that shine a light on the appeal of digital twins. It’s a computing success story that keeps on giving by providing a test bed for new ideas as well as the ability to head off profit-damaging scenarios before they occur.