US educators getting behind Intel and domestic chip fab

Universities in America’s midwest have launched a new network of research and promotion to support Intel’s plans to spend around $20bn on new semiconductor fabrication plants in Ohio.

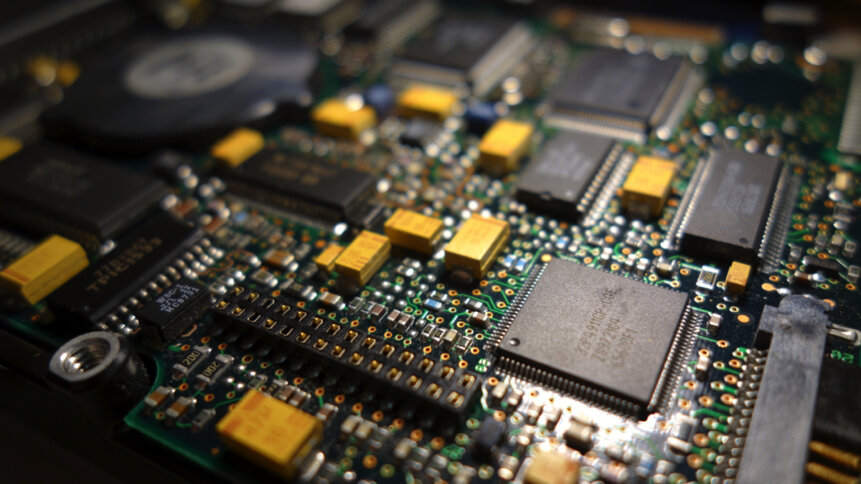

The research and education institutions from Ohio, Michigan, and Indiana have formed “The Midwest Regional Network to Address National Needs in Semiconductor and Microelectronics.” The reference to “national” in the organization’s title reflects a general disquiet in the US administration surrounding the recent supply chain difficulties around semiconductors, problems that have had a significant impact on industries across the country not just the midwest, and of course, around the world.

As a single example among dozens, the European car manufacturing industry for instance has had to limit new car production this year affecting many big name automakers, in some cases halting production lines altogether when otherwise completed cars cannot be sold for want of a few vital electronic components.

The US university network will “leverage its members’ existing research, curricular and experiential-learning initiatives, capabilities and expertise to support a national effort to expand semiconductor and microelectronics innovation and supply chain ecosystems,” according to an announcement by one of the network’s members, Wright State University. Other members hail from Michigan and Ohio State Universities, the University of Dayton, the University of Notre Dame (Indiana) and the University of Cincinnati.

Research institutions like those joining the network have long relied on funding from industry as a valuable source of revenue in addition to government monies, student fees, charitable donations and so on. The relationship between industry and education is, at its best, reciprocal: “Wright State is ready to address the research and educational needs of the growing semiconductor and microelectronic industries while also helping students prepare for new career opportunities those industries will offer,” Dr. Madhavi Kadakia, vice president for research and innovation at Wright State said. Wright State is also offering a new course in Applied Science in Mechatronics and Industrial Engineering, based in its College of Engineering and Computer Science, beginning later this year.

Wright State University graduates have gone on to careers at Intel, and interactions between private enterprises and educational institutions are expected to grow, the University’s site states. The newly appointed chair of the Network is Dr. Subhashini Ganapathy, whose academic position is chair of the department of biomedical, industrial and human factors engineering at Wright, a department that researches supply chain and manufacturing, among other related disciplines.

Big problems at small scales

At present, Intel’s chip designs and existing fabrication facilities are struggling with the smaller miniaturization scales chased by semiconductor manufacturers, with Taiwan’s TSMC announcing that it will be making 2nm chips by 2025 [javaScript obfustication]. The critical difference between companies like TSMC and the US’s Intel is that the former makes chips for a broad range of companies, including Nvidia, MediaTek, AMD, and historically, Apple. That gives the company benefits of economies-of-scale but also an inherently agile approach to its manufacturing capabilities on the factory floor and in its research labs.

And while the oft-quoted AMD vs. Intel competition is going in Intel’s favor at present (the current Alder Lake range of Intel processors is well-reviewed for desktop users, for instance), the differences in miniaturization capabilities between the two is currently quite stark, with Intel still squeezing greater efficiencies from the more power-hungry 14nm designs methods. Packing more transistors into the same space on a semiconductor needs the capability to make things smaller and smaller, so Intel has a hard limit of performance dictated by its 14nm fabrication methods. Its competitors have no such stricture, comparatively.

However, the aim of the US government, Intel, and the midwestern universities participating in the snappily-titled MRNANNSM will indubitably be one of trying to create domestic resources that prevent a repeat of the chip shortages of the last 18 months. What has become evident in the minds of the least technologically-savvy consumer is that chips are in everything, from cars to domestic appliances and all manner of industrial equipment Hence, a shortage has a terrible (and perhaps terrifying) impact on economies both domestic and abroad.