Wi-Fi 6 proves its mettle in IIoT

The promise of 5G is twofold: speed and low latency. In the right settings, the technology has advantages enough to support some intensive business needs, including enabling private 5G networks in closed-loop industrial applications.

Manufacturing and mining, for instance, along with other industrial operations could harness increasingly reliable on-premises private 5G network solutions to manage connected machinery across the factory floor. Increasingly ‘smart’ industries are embracing the operational and cost efficiencies of 5G in edge workflows. When combined with predictive analytics, IoT applications can provide real-time alerts and data gathering to inform operational and strategic intelligence. The market in IIoT is slated to reach an estimated US$344.7 billion by 2026 as per ReportLinker.

IIoT sensors can catch and detect a number of variables from temperature to inventory levels to production outputs. Similarly, devices can work in reverse, changing settings, attenuating controls and generally managing industrial machinery. Sensor data fed into predictive algorithms can often help to inform machine maintenance schedules, for example, preventing problems from escalating and resulting in expensive downtimes.

Technologies like robotics, automated production lines, artificial intelligence-driven predictive maintenance, digital twin tech, and remote facility control & monitoring are becoming termed Industry 4.0 by the technology press. It should be noted, however, that “industry” (manufacturers, engineering organizations, utilities companies, infrastructure providers, mining, and so on) has been leveraging IIoT and by proxy, Industry 4.0 for some 50 years in some cases. What’s new is 5G (and Wi-Fi 6 – see below) networks which bring these innovations together in a functional ecosystem – mostly because wireless networks of any color are often cheaper and faster to deploy than copper or fiber connectivity infrastructure over short distances. In particular, 5G’s range is quite limited without multiple relays due to its use of very high radio frequencies.

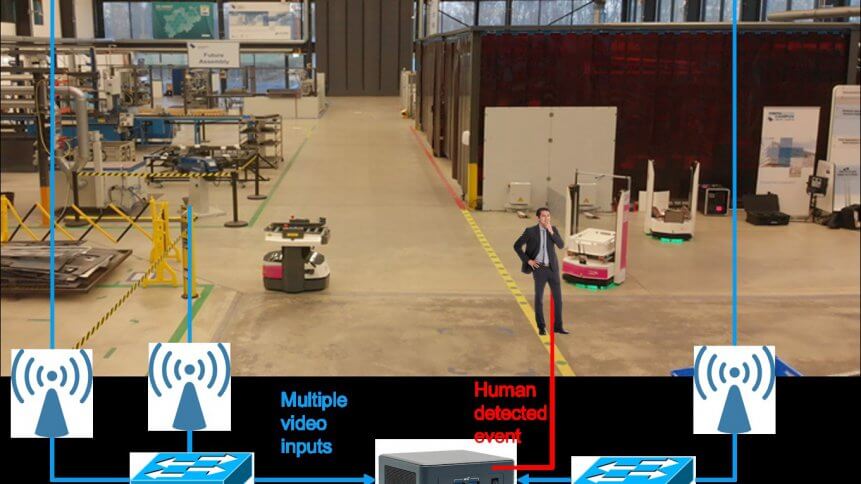

Wi-Fi 6 is well-positioned to support the provision of cost-effective enterprise-level connectivity in an industrial environment. Source: Mettis Aerospace

Despite the surge in interest in 5G adoption, Wi-Fi remains the most prevalent wireless technology in industrial environments. Wi-Fi global organization the Wireless Broadband Alliance (WBA) recently released the Wi-Fi 6/6E for Industrial IoT: Enabling Wi-Fi Determinism in an IoT World report detailing how the latest generation Wi-Fi 6 – already available if not widely deployed – is increasingly the right fit for connecting both existing and newly-emerging IIoT use cases.

The WBA’s IIoT working group consisted of over three dozen vendors and service providers that worked on projects reported on in the whitepaper, including Intel, Cisco, and Deutsche Telekom.

Practical IIoT applications including autonomous mobile robots and ground vehicles (AMRs and AGVs), equipment sensors, safety controls, industrial automotive, location-based services, and wireless time-sensitive networking (WTSN) were all examined to determine how Wi-Fi 6 & 6E performed, and therefore, whether it would prove as viable as 5G, or be better suited to specific use-cases.

Practical IIoT examples

For AMRs and AGVs, Intel and Cisco collaborated with partners to experiment where requirements for network latency were between 10 and 20ms, speed of travel of devices was below 50km/h, and with 99.9999% network reliability. Cisco also worked on safety control applications where latency of less than is essential, such as when an operator leaves their console and automated systems need to take control.

Cisco worked closely with Mettis Aerospace on a test bed for Wi-Fi 6 industrial examples, trialing high-reliability, high-density devices with low power consumption. There was also work undertaken with Intel to study Wi-Fi 6 on AR/VR applications achieving hi-res frame rates of 90fps, where throughput requirements can be as high as 100 Mb/s.

“We’re delighted to be working with Mettis Aerospace and are grateful to the Worcestershire Local Enterprise Partnership for inviting us to collaborate with them to demonstrate the capabilities and promote the convergence of 5G and Wi-Fi 6 in heterogenous networks,” said Tiago Rodrigues, the General Manager of WBA. “This first trial will serve as an example to industrial manufacturers around the world who are embracing the move to Industry 4.0 about the capabilities to deliver transformation with Wi-Fi 6.”

“Industrial manufacturers work in incredibly complex environments, which can make cellular technologies challenging to deploy and operate effectively,” agreed Dave Green, the Head of IT at Mettis Aerospace, in the company’s blog. “We believe that Wi-Fi 6 has a significant role to play within the 5G ecosystem, enabling a range of cost-effective, industrial applications.”