Businesses both big and small spend millions developing and crafting their brand, based on carefully-crafted customer experiences. Reputations in all industries are more quickly lost than built. There is a saying that a dissatisfied customer tells ten people, while a recommendation reaches just one.

And with customer expectations being set high thanks to the convenience of apps and the internet, it’s surprising that many companies seem willing to opt for second-best in their logistics choices. A logistics operator (or logistics function in a larger business) has a significant opportunity, therefore, to differentiate itself from the competition. It does this by providing a service that’s focused on the qualities trusted to it by the brand(s) it works for. At the core of brand values is the end-user’s experience.

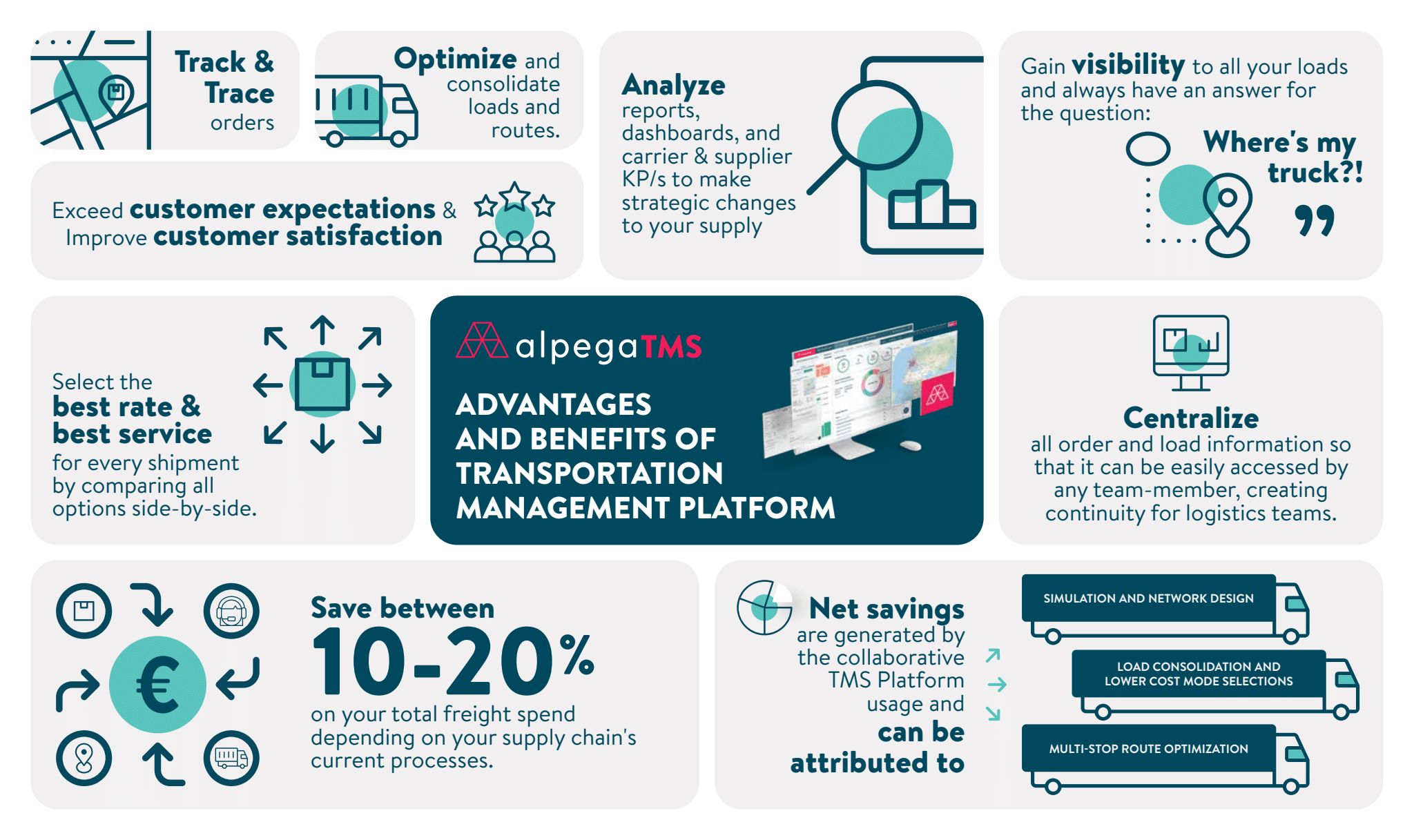

Source: Alpega Group

At the heart of the issue are some seemingly simple enough expectations: customers expect trouble-free deliveries and returns; they appreciate transparent tracking of consignments; they rely on clear communications throughout. Increasingly, too, customers want to use companies where green issues like efficiency and low-waste services are employed, and they rightly expect trustworthiness, as few delays as possible, and overall professionalism.

Shippers successful in achieving these requirements can expect business growth, almost by proxy, but as we shall see, the processes and systems required to provide world-class logistics also enable companies to expand operations effortlessly into new markets and territories.

As you might expect from a website dedicated to business technology, we believe the pursuit of business transport excellence is best undertaken by means of digital systems: platforms that connect inventory management, route optimization, real-time tracking, scheduling and more, right along the supply chain. Connecting a logistics company’s existing systems with those of supply chain partners is important for visibility, and automation can remove a huge amount of manual processing by staff.

Basing operations on digital solutions brings additional benefits, too, ones that are never specifically seen by customers but enhance and optimize logistics operations creating indirect benefits for customers. Information accrued from new-generation logistics platforms becomes a resource for analysis, can have machine-learning algorithms applied to it, and informs strategies to further optimize operations.

To borrow from the vocabulary of software developers, the process of improvement becomes iterative; that is, small changes, one after another, build an improving operation. Vendors of technology often claim, wrongly, that their solutions are immediately revolutionary. It’s important to remember that in supply chain technology, change is brought about by logistics professionals using the best tools, deployed in ways that further the business’s goals. Experienced people who work in business transport know that maintaining standards (and, therefore, reputation) is paramount, and the tools at their disposal are just that: the means by which efficiency and customer satisfaction are achieved.

Attaining superior logistics capabilities is tough in 2024 because of the number of moving parts and the complexities of everyday operations right along the supply chain. The best business transport management solutions reflect the number of entities present (like third-party partners) and the variables involved, adopting a modular approach to required capabilities.

At the same time, it’s important to recognize that despite complexity, there must be clear oversight over the entire range of operations. With that, the possibilities of automation and simplification become apparent. What were previously nice-to-haves like, for instance, a real-time, informative customer portal become relatively simple to implement.

At its core, a good business transport software system is data-driven, but is primarily a set of tools used by experienced logistics pros who know their business and are able to enact the business’s strategy: for improved customer experience, for efficiency and lower cost, and to build market differentiation.

Source: Alpega Group

The data grounding of today’s logistics management systems creates possibilities, too. Modeling of potential changes becomes lower-risk, because so-called ‘digital twins’ – the trialing of new ideas and strategies – mean that customers are not unwitting guinea pigs for experimental change. The digitally-fluent company can base its strategies on empirical data from existing operations, data that can be enhanced by third-party information sources and processed by algorithms designed for the industry. Modules that connect supply chain partners’ systems to give wider, deeper knowledge to the logistics operator create the basis on which true customer satisfaction is based. To use some marketing terminology, customers in time can become brand advocates.

When global events and local conditions affect supply chain and sourcing, from regional conflict to labor shortages, the challenges to achieving BTE (Business Transport Excellence) are many. A reactive approach to problems is sometimes unavoidable, well outside the control of the individual. But a proactive approach to choosing and using platforms and systems on which logistics operations take place is possible. Of the best global players in cloud-based, extensible transport management systems is Alpega. In 2024, it launches its “Business Transport Excellence” platform, bringing together all its solutions for shippers and carriers in a single platform. The integrated approach reflects how supply chains work and what they are capable of.

To find out more about Aplega’s offerings and how they can instill differentiating change, contact a representative near you today.