IBM predicts the rise of cognitive supply chains

Supply chains have become crucial focal points for technological innovation.

As technology enables greater competition and scale than ever seen before— and meeting customers’ expectations more demanding— businesses can live or die on the efficiency of their supply chains, and their ability to run flawlessly around the clock.

These challenges have contributed to the development of “game-changing” automation technologies and platforms, from factory robotics to RPA, deployed to assist and centrally manage a complex web of moving parts often across tens or even hundreds of distributed companies or departments.

Powering increased productivity while reducing manual input, automation will accelerate the productivity of the global economy by between 0.8 percent and 1.4 percent of global GDP annually, according to McKinsey. Thus, supply chain automation is both cost-effective and drives higher profitability.

But as we roll into a new decade, and with the pursuit of continuous disruption now the norm across almost every industry, companies are flocking to the latest innovations in efforts to put themselves a pace ahead of competitors.

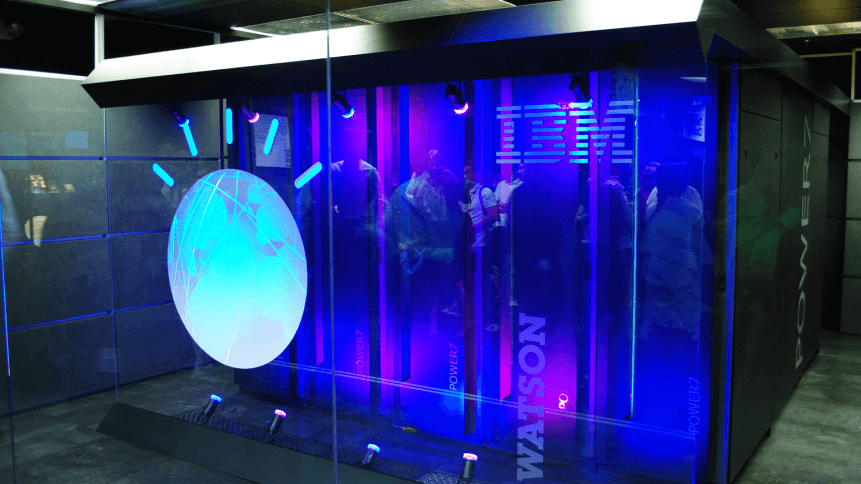

As such, supply chain technology continues to evolve, and IBM predicts the next stage in this development will see the emergence of the “cognitive supply chain”.

Powered by advanced AI, cognitive computing and cloud technology, the supply chain will not only be majorly automated, it will become self-learning, able to predict and act on a wealth of proliferating data sources, from market trends, scarcity, demand, competitor behavior, and more.

According to the report, close to 50 percent of supply chain executives across industries believe the “catalytic properties” of this technological convergence will restructure supply chain processes over the next three years.

At ICDXA 2020 in Kuala Lumpur, Malaysia, Steven Hurley, Data Scientist and Solution Architect at IBM Supply Chain Engineering’s Analytics Solutions Group, told TechHQ that as we move towards the “fifth Industrial Revolution”, artificial intelligence will become a “pervasive” technology in manufacturing and supply chains.

Supply chains will continue to be instrumented with data collectors, such as IoT sensors, GPS and RFID tags, he explained, while advances in connectivity will result in a more tightly structured web between stakeholders and devices, leading to more accurate decision-making.

As a result, the sharing of advanced analytics and modeling across supply chain members will enable a transition to systems being equipped to make decisions autonomously, not just informing the decisions made by those overseeing them.

This concept isn’t just a product of future-gazing, Hurley said it’s emerged from IBM’s close relationships on the front-line of manufacturing and supply chain technology.

“We realized we had lots of data and organizations are keeping their own data. If we were able to bring that together and make it transparent, putting together the tooling, the dashboards and using the analytics, we would have greater insight into how we were running their business and how we can make it more efficient,” he said.

“[…] we’ve put a lot of technology in place to support that. Now we’re working very aggressively to build upon that platform and add artificial intelligence and use it very pervasively within our operations.”

For instance, machine learning algorithms can be deployed to massive operational data feeds to identify data patterns and predict supply chain disruptions, providing an added layer of visibility and clarity to daily operations.

ML capabilities also provide alternative routes and paths in the event of a disruption or natural disaster.

The road to cognitive supply chain

With the application of AI in the business proving to be an undertaking that takes considerable time and planning, graduation from an automated supply chain to a cognitive one is a staged process.

“You try to implement the technologies and analytics to get into this smart factory kind of mode, and then begin adding the artificial intelligence to get to ‘cognitive’,” Hurley stated

The most important piece of this isn’t the technology, Hurley added, it’s having a very clear vision of where you want to go and being disciplined about getting there, and that vision has to cover multiple bases.

“It’s not just technology. It includes technology, but it also includes the processes that technology supports.”

In the supply chain, where the stakes are high and each day can bring immense, unexpected challenges or setbacks, the rise of cognitive computing could enhance all areas of management.

YOU MIGHT LIKE

Five tips from IBM’s CDO on how to make an early impact

As an example, in manufacturing, procurement staff generally lack time to compile and analyze the volume and pricing details of all suppliers, especially among smaller partners which could number in their thousands.

To promote more data-driven decision making among procurement specialists, a local company developed an AI-based procurement platform that analyzes all suppliers under a single lens, gathering unstructured data from within and outside of the organization and visualizing it in forms accessible for decision-makers.

These programs could be developed further to automatically select the best partners to work with, based on pricing, location, volumes, in accordance with external data, such as weather, for example,

Meanwhile, an advanced earphone manufacturer from Germany incorporated cognitive IoT platform services to improve worker productivity in its factories. Workers were able to use simple verbal commands to retrieve complex information and receive personalized messages to assist them in completing their tasks more efficiently.

The path to success in supply chain management needs to be strategically planned and ruthlessly executed. The majority of financially robust companies follow a transformation roadmap, which includes a flow of launces and innovations.

By organizing workshops to keep stakeholders in the loop, alignment of company goals, digital transformation, and visualized results becomes easier, facilitating communications and achieving higher gains.